Engineering Services

ICE does keep on-board the capacity to handle most aspects of engineering commonly found in the process industry. That said, it is most common for us to focus on the process engineering, automation systems engineering and operational integration.

FRONT END

ENGINEERING & DESIGN

PROCESS

ENGINEERING

PROCESS CONTROLS

ENGINEERING

ELECTRICAL

ENGINEERING

Process System Design & Engineering

Using our process system engineering and physical design capabilities, ICE has experience developing custom modular process systems for your company’s proprietary base process technology. Depending on the size and scale of the project, we can offer full plant design services or simply customer representation to larger engineering firms.

ICE’s process engineering and design is most experienced with projects at demonstration and small industrial plant scale. We offer experience with larger, high-integrity industies adapting those practices addapted to smaller capital budgets.

We have connections to partner with industry-specific process engineering firms for larger scale projects be they greenfield, brownfield, or plant expansions. We also have foreign engineering service contacts that often offer bulk-rate services for the labor intense segments of the process and mechanical engineering, often cutting the cost of large portions of engineering by 30% or more.

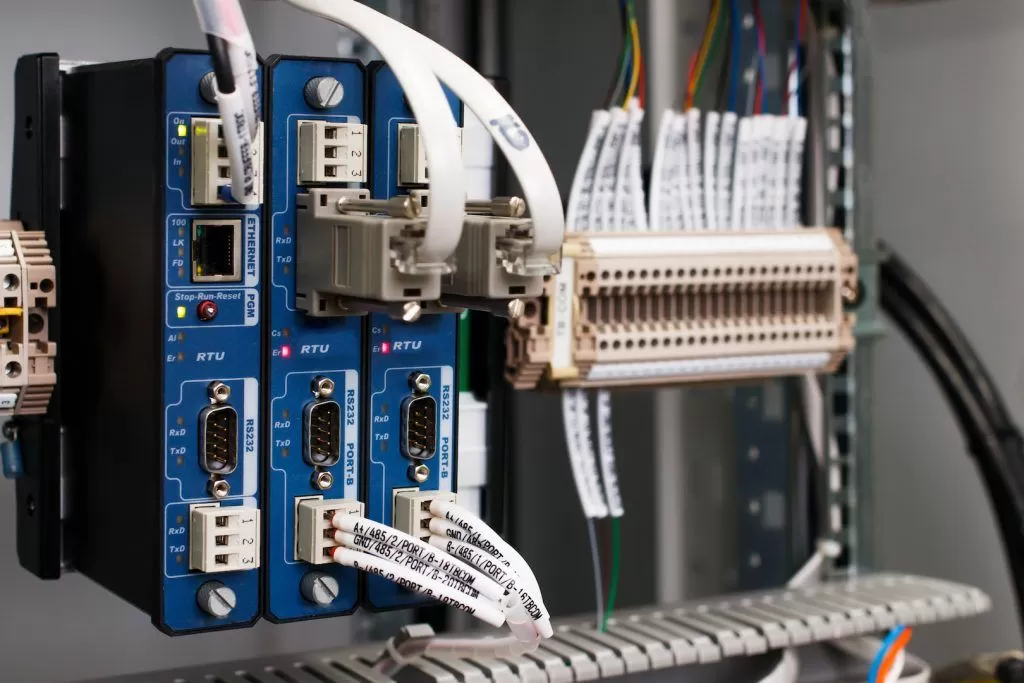

Process Controls Engineering

Process Controls is at the heart of ICE’s competency. When considering process controls and data integration, either as part of a larger project or as a stand-alone capital improvement, ICE is comfortable taking on any scale project. Our team includes a full portfolio of personnel with process engineering and process control experience from Junior Engineers to Senior Level Experts. Our disciplined engineering and creative solutions ensure the system delivered is tailored to the client’s needs and processes.

Front End Engineering & Design

Front End Engineering & Design, also known as FEED, is the engineering performed to determine the cost of the plant build and project. ICE provides numerous levels of FEED services designed and detailed to suit each client’s specific needs. Unlike larger firms, ICE does not require defined services to be identified on a manager’s P&L statement. We are offer no-cost, low cost, or mid-cost services and has access to higher level FEED’s.

We value client-direct experiences in the early stage of process R&D and have developed estimates for FEED costs based on the level of development of the process and the expected budget. ICE has a firm grasp on how much pilot plant and demonstration-scale plants should cost and the derivative cost of the investment in FEED exercises and offer guidance gratis.

Industrial Electrical Engineering

ICE Process Management will take on electrical engineering from the 480 Volt distribution down to any lower volt rating. This includes:

- Motor Control Systems

- Power Distribution Panels

- Controls Panels

- Area Classification & Rate Enclosures

- Instrumentation & Device Location

Where projects require other electrical engineering services, ICE has preferred partners and is happy to work with client-preferred partners. This would include such services as:

- Transformer, Switch Gear and Auto-Transfer Switch design

- Power Distribution Designs

- Grounding Designs

- Lighting Design

- Lightning Protection